CHANGING YOUR COPPER

Use the flathead screwdriver to hold the screw head in place on the bottom of the cooler.

Next use the wrench to turn the TOP NUT inside the cooler.

Once the nut is loose unscrew the top nut completely and remove the ring terminal from the screw.

The ring terminal is the silver connector attached to the wire.

Now the ring terminal is disconnected from the screw.

Place wrench on remaining nut and brace the screw head with the flathead screwdriver. Loosen the remaining nut and remove from screw.

Once nut is removed pull screw out from hole in base and remove copper.

The old copper is now out of the cooler and ready for the new copper to be put in.

New coppers come with fresh nuts and screw.

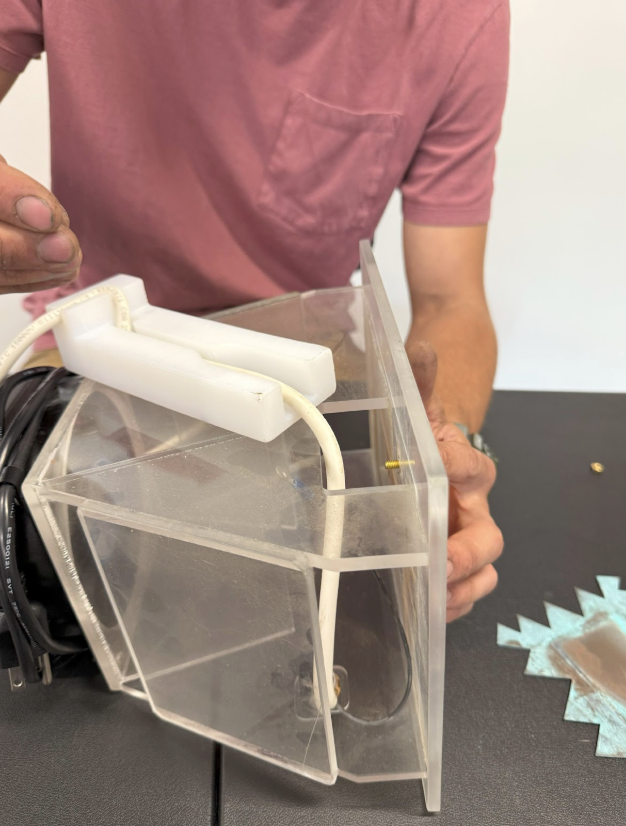

Flip your cooler upside down for easier access and wipe off any dust or residue on bottom of cooler.

Thread brass screw into the hole in the new copper then put screw and copper into the base.

The copper should fit in the indented area with relatively even space between points on copper and the edges of indented area.

Tilt cooler on its side and thread first nut onto screw.

Using flathead screwdriver to brace the screw head, lightly tighten the first nut with 11/32” wrench until copper is secure.

Once first nut is secure put ring terminal back onto the screw, then add second nut on top of the ring terminal.

Now that the second nut is over ring terminal lightly tighten the top nut with wrench until secure and ring terminal does not move freely.

Using the wrench lightly tighten the nut, notice how he uses his fingers to hold the screw in place while tightening the nut

It’s very important that the wire does not touch the copper or sit over internal cutout.

This picture shows incorrect wire placement.

You are now ready to put the cooler back onto the base.

Make sure:

The copper is over the foil.

The black line is lined up to the opening of the cooler.

If you do not have a black line on your clamp block you can align edge of block about 1/8” away from the internal cutout over copper.

Now insert the brass screws into the clamp block and screw them into base, do not over tighten.

Congratulations you changed the copper!

Before you turn your Enhancer on, remember to plug the bulb into the cooler and the fan cord into the back of the white power box.

Images of coppers that are ready to be changed.

Notice how the points are rounded on the top copper and both coppers are thinner than a fresh copper.

The bottom “bluish” copper has more blue deposits but could be cleaned one more time before having to replace it - visit HERE to learn how to clean your copper.

Upper Right shows a new copper in comparison to the other 3 coppers that need to be replaced.

To start you will need a flat head screwdriver and a 11/32” wrench.

We like to wrap the fan cord around the fan to keep it out of the way.